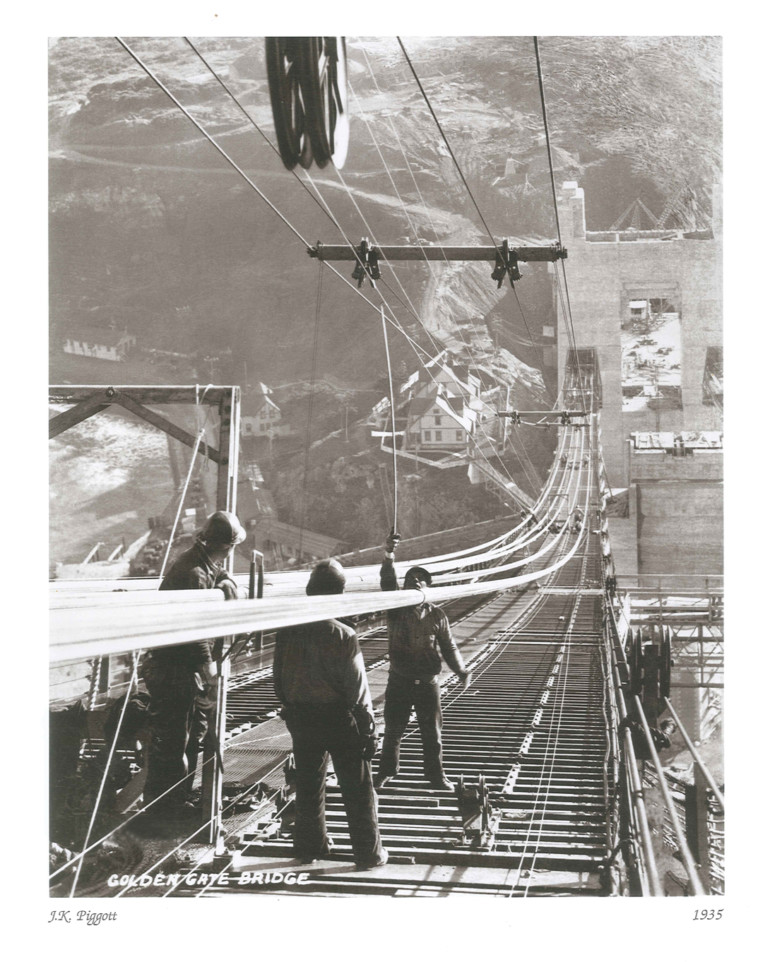

BEFORE CONSTRUCTION STARTED on the Golden Gate Bridge, engineers calculated that the two main cables for the suspension bridge, including the cables that would hold up the roadway, would weigh 24.5 tons. “It was (and still is) impossible to fabricate these cables on land and then raise them 746 feet in the air and place them atop each tower,” reports Mill Valley author James W. Schock in his book The Bridge: A Celebration. “So the only answer was to fabricate them in midair.” And fabricate them they did. In this 1935 photo of the San Francisco side of the Golden Gate Bridge, a worker is separating a 9/16-inch wire (about the size of a water hose), one of hundreds holding up the catwalk the workers are standing on, from a 3/16-inch (the width of a pencil) galvanized steel wire that is being “spun” out of the galley wheel at the top of the photo in a process called “cable spinning.” And when that 3/16-inch galvanized steel wire was combined with 27,572 other pencil-size wires, it became one of the two main cables of the Golden Gate Bridge. The two cables each stretch 7,650 feet between San Francisco and Marin County with a graceful sag in the middle, essentially holding up the roadway. According to Schock’s book, Joseph B. Strauss, the bridge’s chief engineer, said 452 of the pencil-thin galvanized steel wires were banded with heavy-duty steel tape into 61 bundles — 452 times 61 equals 27,572 — then packed tightly together to form a main cable with a diameter of slightly more than one yard. In all, the two main cables, thanks to 117,000 splices, hold 80,000 miles of pencil-thin galvanized steel wires — enough to circle the earth three times with a round-trip to New York left over.

This article originally appeared in Marin Magazine’s print edition with the headline: “Looking Back: Suspension Story”.